There is now a global effort to modernize power systems towards a “smart-grid” based on renewable energy and new paradigms for power distribution, storage, and consumption. This change is motivated by many factors, including environmental compliance, economic advantage, and improved reliability, robustness, and service. Research in this area extends beyond private and academic institutions, and is now a centerpiece for clean-energy initiatives in the United States, Israel, and the European Union.

Renewable energy, in particular solar and wind power, are intermittent energy sources whose production quantity fluctuates with natural cycles seasonally and geographically and require new strategies for power generation, storage, and usage. On the other hand, the major increase in fuel consumption for power generation in industrialized countries is foreseen to be fulfilled by natural gas. The European Union’s electricity generation from natural gas has tripled in the last 10 years. In Israel, the newly discovered gas fields within its territorial waters are enough to address the electricity needs of the entire nation for the upcoming 50 years. Hence this type of shift towards natural gas is also anticipated in Israel.

The largest increase in the use of natural gas for power generation will principally be accommodated by the continuing introduction of gas turbines (GT), mainly in combined cycle forms. Moreover, the trend towards deregulation of the electricity supply market vastly enhances the emerging distributed power generation for efficient distribution of electricity and minimizing transmission losses over long electricity lines. Applying the distributed power generation concept, numerous small and efficient gas turbine units will gradually be introduced in order to fulfill new demands and to replace few of the large aging power plants. Therefore, there is a particular interest in the potential of technologies such as MGTs, especially in combined heat and power (CHP) applications and poly-generation systems, where the local main energy consumers become the provider for their electricity, hot water, heating and chill production. Consequently, the non-centralized energy infrastructure network becomes more robust, cheaper (gains in distribution losses), safer, and also versatile (peak shaving). Natural gas in a combined heat and power cycle is the most cost effective technology available today and has high potential for distributed implementations. The integration of MGTs into the smart-grid can be approached as an economic dispatch (ED) and unit commitment (UC) problem. The ED and UC problems determine an optimal schedule and commitment level for each generating unit in a power system based on a set of constraints, including reserve power, operating parameters, and forecasted loads over a finite time horizon. In a smart-grid scenario where power demands should be mitigated locally, a detailed model-based optimization strategy has the potential to offer significant improvements over standard ED and UC approaches. While many optimization-based approaches to the operation of the smart-grid are currently being considered, a focused effort for optimally integrating a network of micro gas turbines has not yet been considered. Owing to the clear advantage of MGTs in a smart-grid environment, we have solved the unit commitment and economic dispatch problem of a micro gas turbine in CHP operation for smart grid applications.

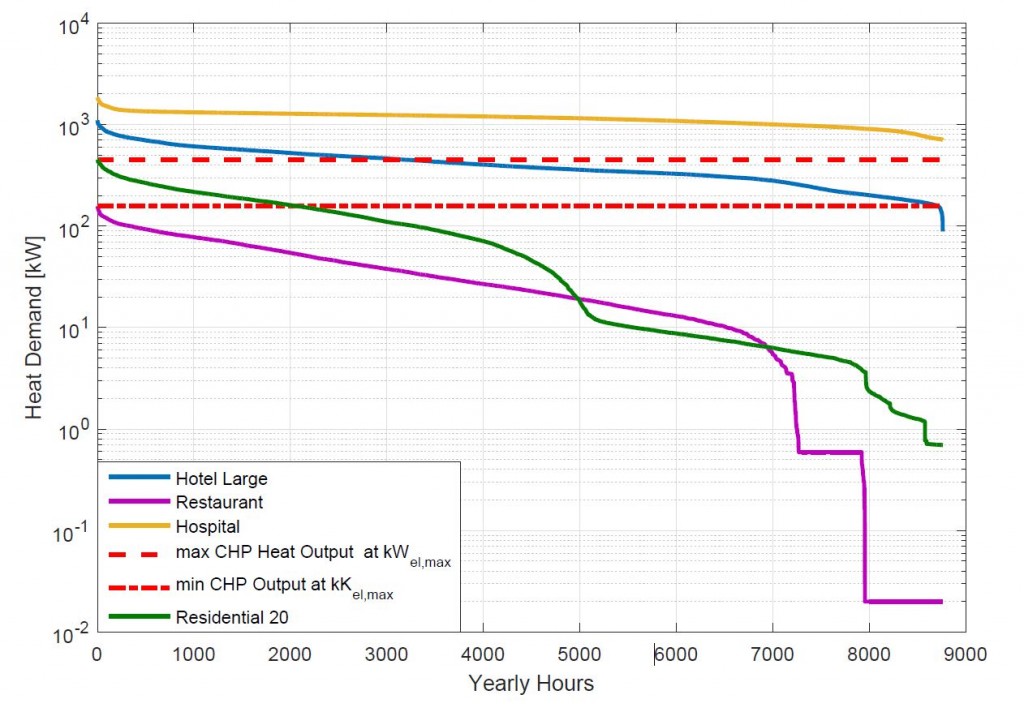

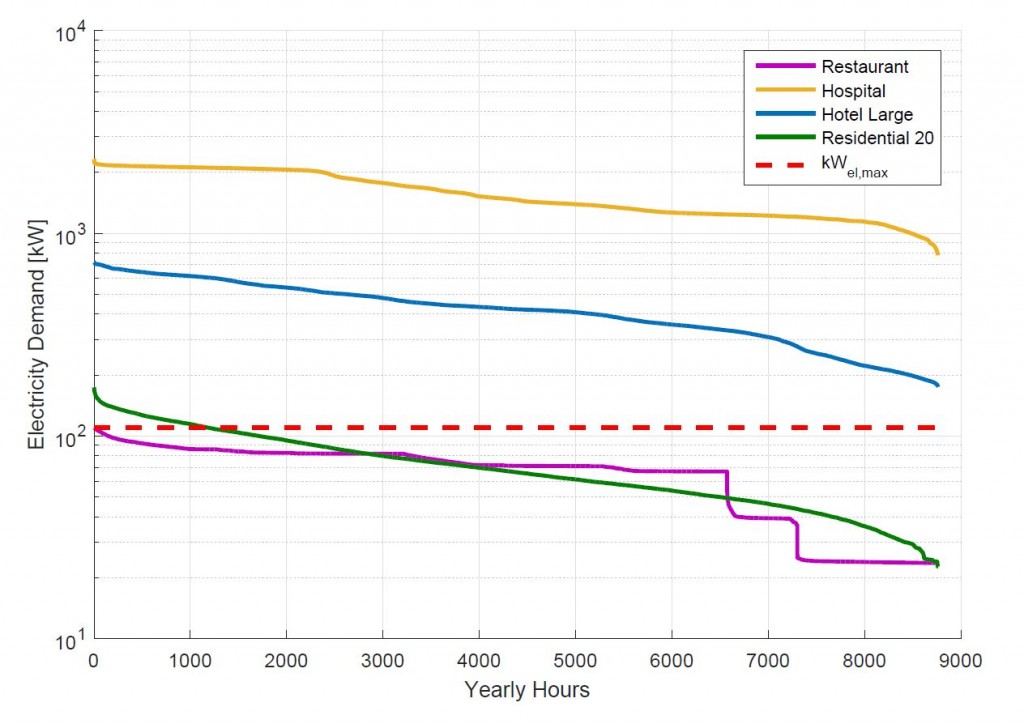

To demonstrate the benefit of integrating the MGT into the energy market, four detailed customer profiles were considered:

- A hospital – floor area of 22,422 m2 over 5 levels.

- A large hotel – floor area of 11,345 m2 over 6 levels.

- A restaurant – floor area of 511 m2 on one level.

- A neighborhood consisting of 20 residential buildings.

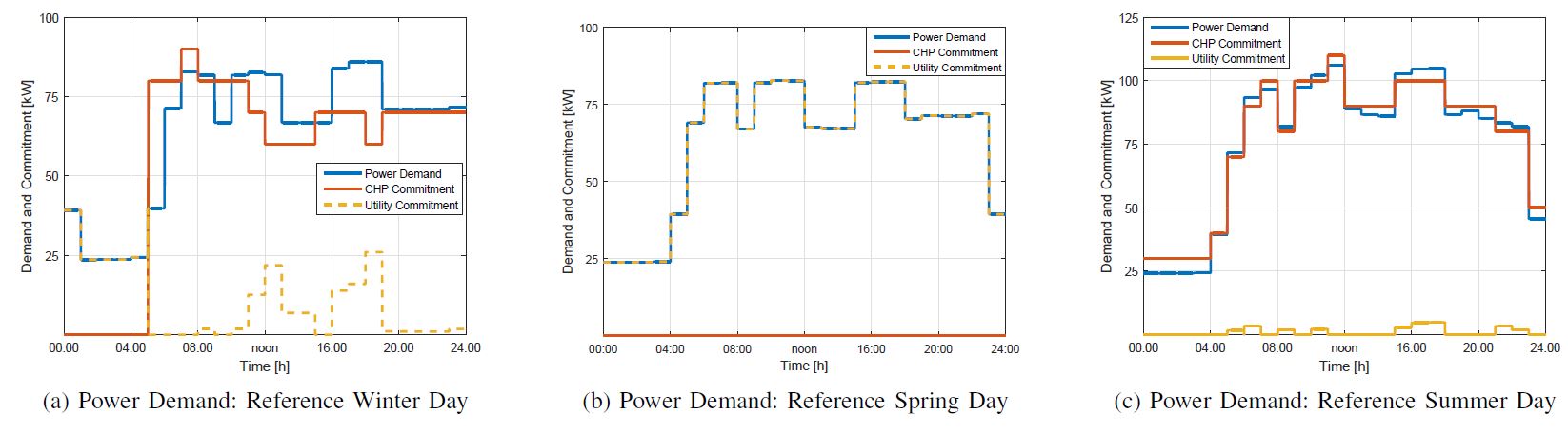

In the figures, the two horizontal red lines show the minimal and maximal heat output and maximal electrical power output. Thus, it was possible to conclude that while the MGT can meet the entire heat demand of a restaurant over a calendar year, for larger buildings (such as a hospital), it is not possible. For the other buildings types, the heat demand supplied by the MGT should be determined according to time-varying demand level and the cost of providing heat. Three reference days were considered to represent typical seasonal variations during summer, winter and spring/autumn. The economic dispatch problem was solved for all representative cases and unit commitment charts were obtained. For example, the CHP unit commitment to power generation for a restaurant is presented below:

The blue line in the figures represents the power demand of the restaurant, the red line depicts the power provided by the CHP unit and the yellow line shows the power bought from the main grid. A net present value analysis was performed based on the results of the simulation runs. The investment costs for the CHP unit were considered to be $150,000 with annual maintenance costs of $4,400. The net daily savings were estimated to reach ~ 150 USD, depending on gas prices.