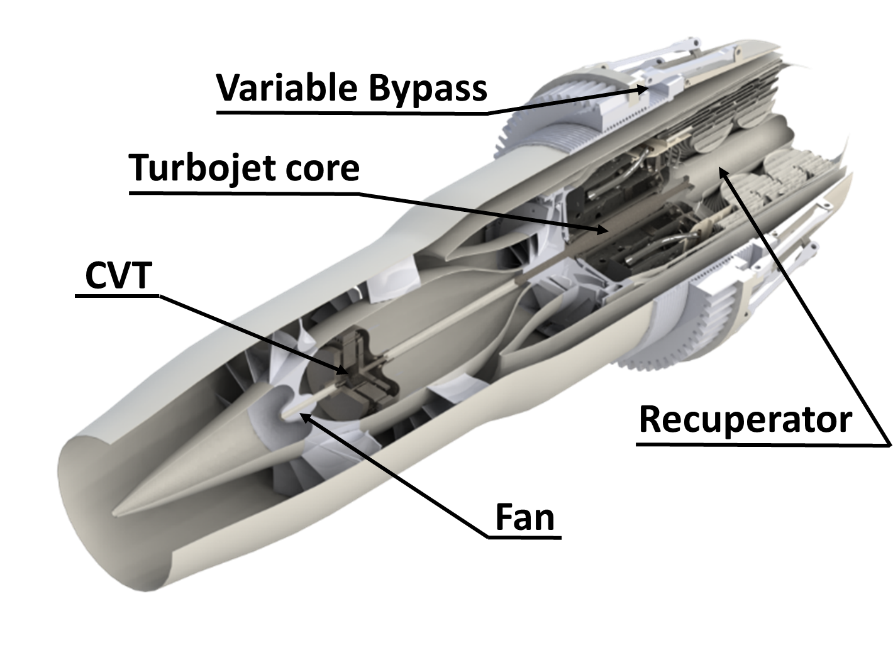

As the operational envelope of unmanned air vehicles (UAVs) expands into the high sub-sonic and transonic speed range, the engine design process requires compromises in thrust, weight, fuel consumption, size, reliability, and manufacturing cost. Moreover, the engine requirements for multiple operating points, consisting of loitering during reconnaissance and high-speed flight during cruise, are conflicting as design criteria for an efficient propulsion system. In general, micro-turbojet engines may offer a simple design capable of providing high levels of thrust, but are marked by poor fuel consumption, hindering range. In contrast, larger platforms utilize turbofan engine architectures due to their greater propulsive efficiency at low flight velocities. The goal of our project is the development of a variable cycle micro gas turbine engine, which operates via integration of a fan by a continuously variable transmission (CVT) into an existing micro-turbojet with an adaptive bypass nozzle. The developed solution significantly improves maximum thrust, reduces fuel consumption by maintaining the core independently running at its optimum, and enables a wider operational range, all the meanwhile preserving a simple single spool configuration. Moreover, the introduction of a variable fan coupling allows real-time optimization for both “fly-fast” and “loiter” modes.

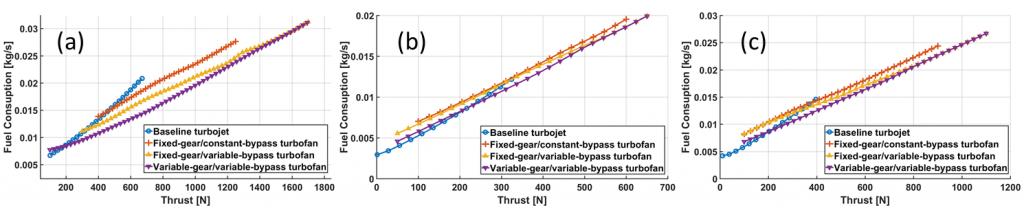

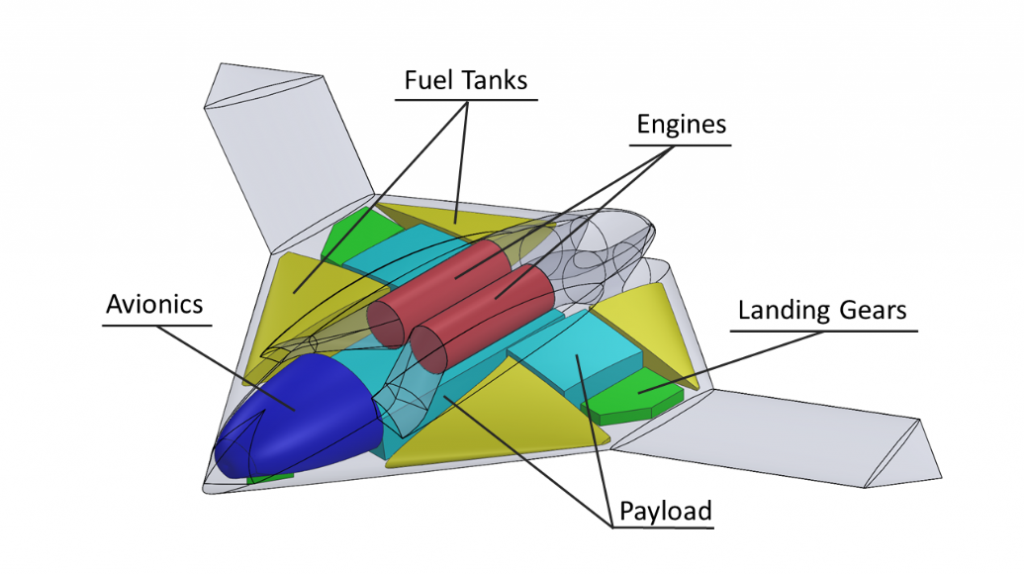

The potential performance of such engine and its benefits are highlighted in a representative surveillance mission, where a remote location is considered to suffer from a natural disaster. Thus, UAV powered by two adaptive engines will be sent to support the rescue efforts. The UAV will ascend to 9 km altitude and cruise towards disaster region at Mach 0.9. Then it will loiter 5 km above the target for maximal time possible. During this simulation we compared performance of different engines architectures. The UAV powered by variable-gear/variable-bypass turbofan showed superior performance and was able to stay 60 minutes more above the target location, resulting in 20% additional loiter time in comparison to other propulsion systems. We are currently in the process of constructing a testbed and assembling a demonstrator unit to carry our experimental study and assess the performance of the engine after the conversion process.