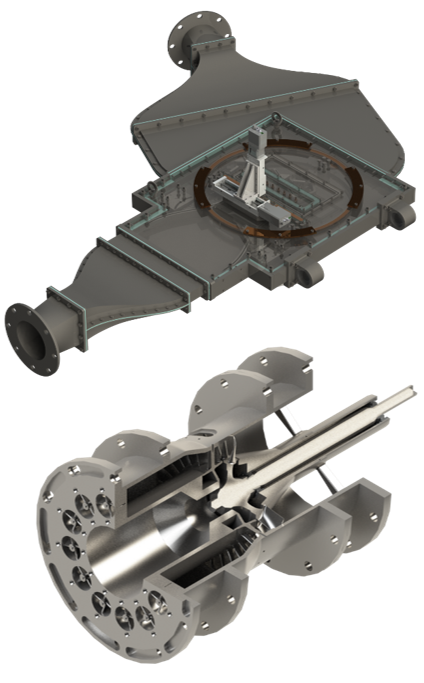

Beyond the inherent design complexity, the physics associated with micro gas turbines are complicated by dimension-specific challenges. Hence, to obtain positive cycle efficiencies, the same design guidelines cannot be applied to large and miniaturized engines. Currently, among the main technological barriers of advanced micro gas turbine development is the lack of relevant scientific knowledge on the hot gas section, which is commercially confidential and export-controlled. In this light, we are building Israel’s first turbine research facility, which will enable developmental projects to be structured around a versatile closed-loop pressurized high speed turbine facility. Incorporating an interchangeable test section to provide hot (~600K) transonic conditions for fixed blade cascade and rotating high/low pressure turbine stages of micro-engines, it is intended to provide unique research capabilities to the global research environment. The final specifications include maximum turbine diameter up to 350mm, closed loop turbine pressure ratio up to 6:1, maximum mass flow rate of 0.9 kg/sec, transonic Mach distribution on the blades, rotational rate of up to 90,000 rpm and flow to metal temperature ratio of up to 2:1. Matching all engine similarity conditions for high pressure turbine stages of micro-engines, the continuously running rig will enable full aero-thermal performance characterization of the turbine independent of other sub-components and contribute to advances in the areas of advanced thermal management, active tip clearance control and aerodynamic/thermal loss minimization.

This work was also featured in the Engineering Edge magazine.