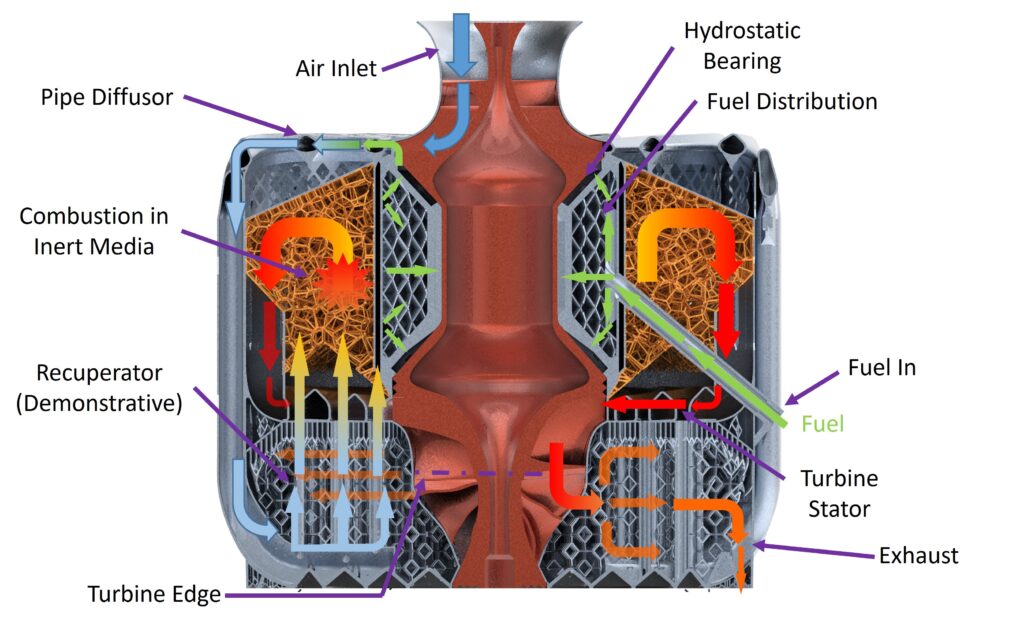

In modern defense applications, small unmanned aerial vehicles are powered by micro-gas turbines that have manufacturing complexity, supply chain dependency, and demanding maintenance schedule that translate into disproportionate cost and interrupted availability, which negatively impacts operational readiness of the platforms incorporating them. Despite the relatively simple topology of conventional micro-turbojet engine, its traditional production involves complex scheduling of long processes due to the presence of numerous parts and different manufactures, including turbine casting, compressor milling, shaft turning and grinding, and combustor sheet metalworking. In the following, together with the coating and bearing providers, all these parts are assembled by qualified personnel. Instead of relying on this conventional process, the concept proposed here entails development of a non-conventional engine designed for additive manufacturing to produce the propulsion system in its final topology through a single uninterrupted print that encompasses both the rotating and stationary components. While architecture benefits from inherent advantages of additive manufacturing including fusion of parts and complex internal geometries, the design is also required to accommodate the manufacturing technique constraints such as self-supported structures, maximum cantilever angle, minimum wall thickness, minimum hole diameter, and absence of precision surfaces. Considering the print volume of the currently available metal 3D printers, the target gas turbine design has a diameter of up to 25cm, thrust rating of 700 N and air mass flow rate of about 1.4 kg/s. The gas turbine includes only two major parts – a static casing with an embedded combustion chamber and a rotating shell structure. This rotating part spins at a rate of 50,000 rpm and includes compressor and turbine impellers connected by a hollow shaft. The rotor also serves as a fuel driven hydrostatic bearing. The fuel is subsequently evacuated through perforated media towards the compressor-diffuser region and mix as an aerosol with the incoming air flow. In a pursuit to reduce engine size, a porous media combustor is used to burn the premixed fuel-air mixture which in turn increases the operability range of the combustor. The rotating component of the micro gas turbine is designed to be balanced after the manufacturing process only through ad hoc removal of mass from dedicated external surfaces.

Towards developing the necessary technologies to accomplish this goal, the Turbomachinery and Heat Transfer Laboratory of Technion-Israel Institute of Technology has been leading the multi-disciplinary turbomachinery design process in collaboration with PTC, von Karman Institute for Fluid Dynamics and Izmir Katip Celebi University. The activity has been funded in part by the NATO-Science for Peace and Security Program. The enabling technology is a novel turbomachinery architecture that consists of two self-supported concentric parts – a static porous media combustor and a casing with an embedded hydrodynamic fuel bearing surrounding a rotating monolithic shell structure that includes a radial turbine mechanically driving a centrifugal compressor. Requiring only a laser powder bed fusion printer and an operator, the cost of the engine will be diminished to capital equipment depreciation and raw material, with on demand availability of propulsion system to platform operators.

The research ideas were realized in digital modeling and simulation-led design of the entire engine topology in Creo, a PTC Technology CAD software. Furthermore, EOS Systems helped to complete the digital thread through implementing the efficient process for additive manufacturing. Using Inconel 718 powder, the final geometric proof of concept demonstrators were printed by The Israel Institute of Materials Manufacturing Technologies, affiliated with Technion’s Research and Development Foundation, on EOS M290 and by EOS Systems on EOS M300 printer.